Steel Constructions

With the help of modern production equipment and a flexible production facility, Prodtex can supply a wide range of steel structures. We are very committed to preserving the environment and are continuously working to achieve the most energy efficient production processes possible. This in addition to local production and environmentally friendly material allows us to deliver quality products to our customers with a low CO2 footprint. Prodtex is approved in accordance with EN 1090 and can supply CE-marked steel structures.

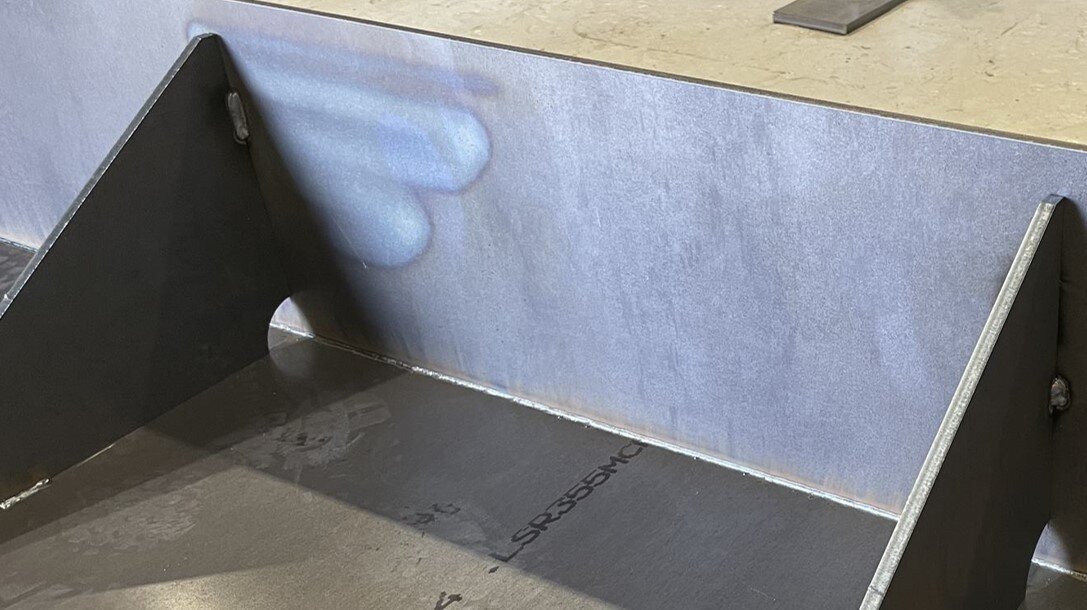

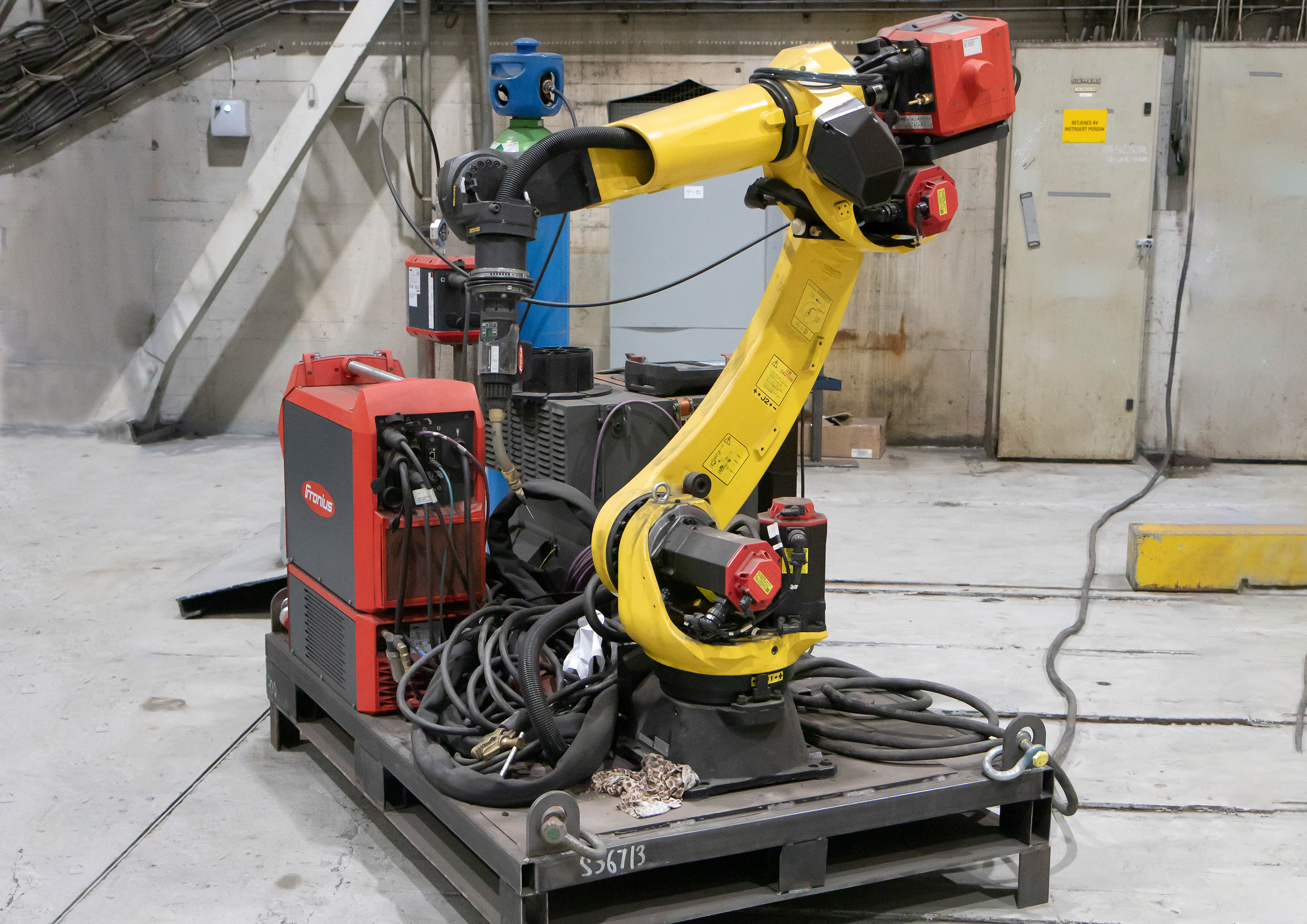

High precision products

Various mechanical installations such as machinery and processing equipment often requires a high level of accuracy. Our production facility is well equipped to accommodate manufacturing of such products.

Robot tools and fixtures are developed to enable manufacturing of both small and large sized products which require precise handling and assembly. This both decreases lead times and minimize the need for post processing after welding.

Other structures

With experience from offshore, infrastructure and component manufacturing, our team offers project management, engineering and realization of a large variety of products which will satisfy the customer’s needs and requirements.

Our main field of specialty is manufacturing and handling of both large and smaller steel constructions such as e.g. plate and beam assemblies, sandwich elements and offshore equipment.

We offer full project implementation, from concept and prototyping to the finished product, as well as maintenance and service agreements.

We always aim to develop solutions that meets the standards for modern fabrication and efficiency.

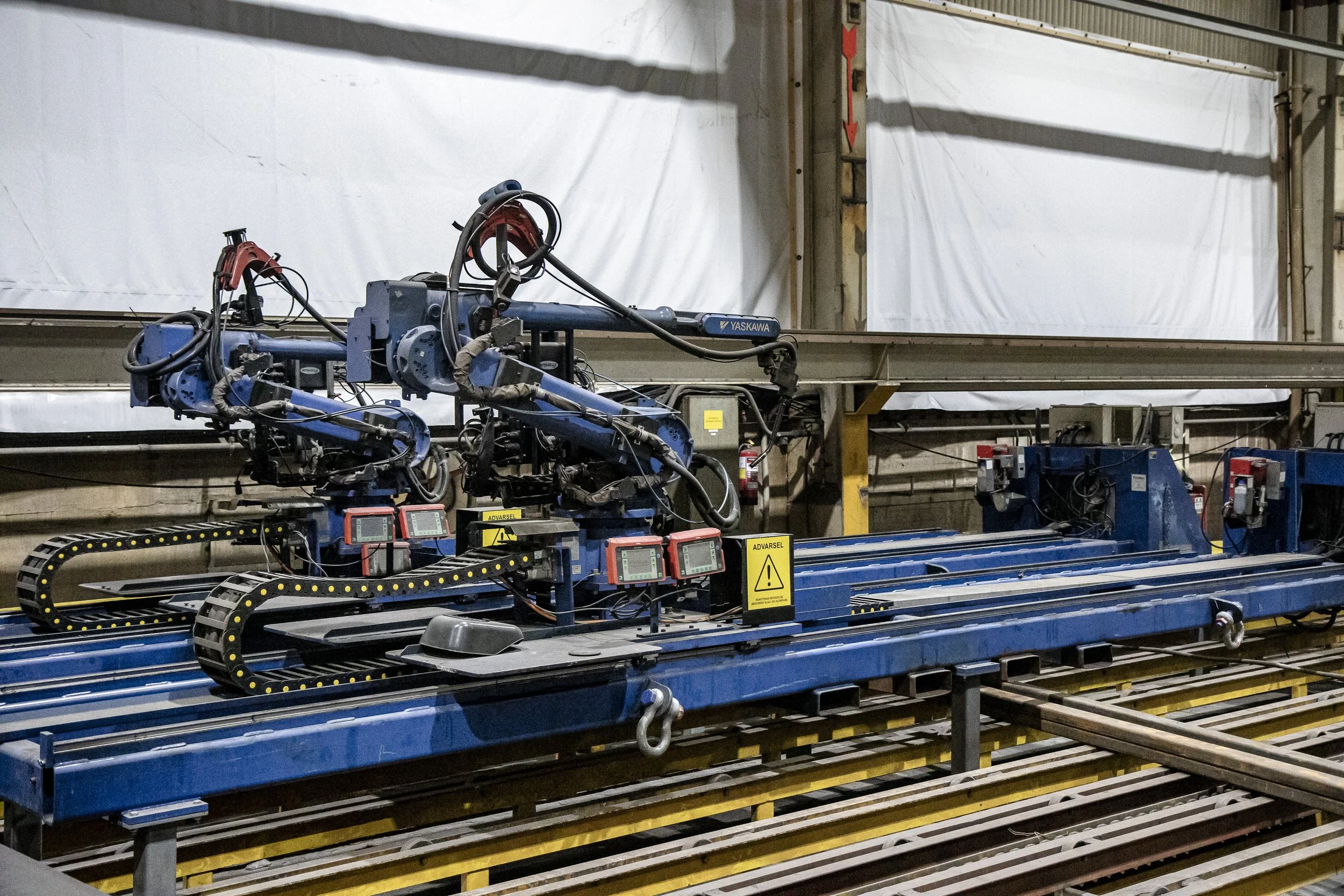

Steel bridges

By combining laser technology with automatic handling of materials and welding processes, we have developed a highly efficient manufacturing process for the construction of steel bridges. Our workshop at Fiskåholmen has a length of 130 meters that enables the construction of long bridge elements indoors. The site has a large outdoor area that allows for assembly of large elements or intermediate storage, as well as launching and loading for transport by sea or road.

Laser welding enables us to design and manufacture steel sandwich constructions - lightweight and high-strength bridge elements.

Offshore wind

Ambitious plans for offshore wind power requires a significant increase in production capacity in Norway and Europe. To cut the large emissions from transportation of voluminous substructures for turbines, the production should take place as close to the site as possible.

At the Prodtex facility at Fiskå, the space for prefabrication of elements inside the hall is 24x20x55 m. Outside is a large area of 25.000 m2 for assembly into larger elements or complete substructure, and there is an ongoing zoning plan for land reclamation, increasing the area to approximately 50.000 m2. Utilizing automated robotic welding, especially laser and laser-hybrid welding, on the heavy steel plates in these structures will give production speeds that significantly outperforms manual welding. This is key for achieving the megawatts that needs to be produced every year.